September 21, 2019

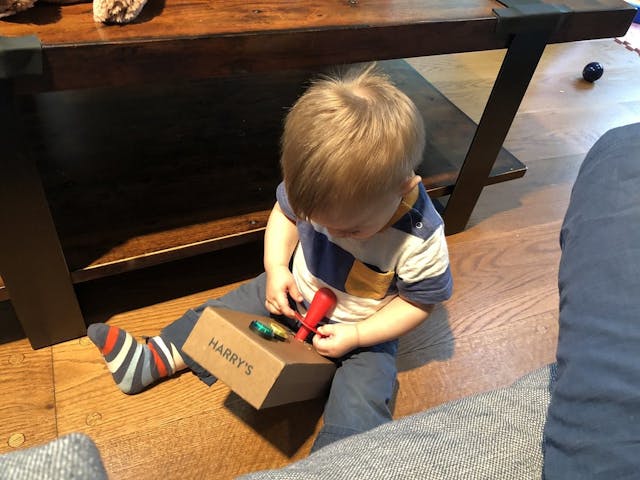

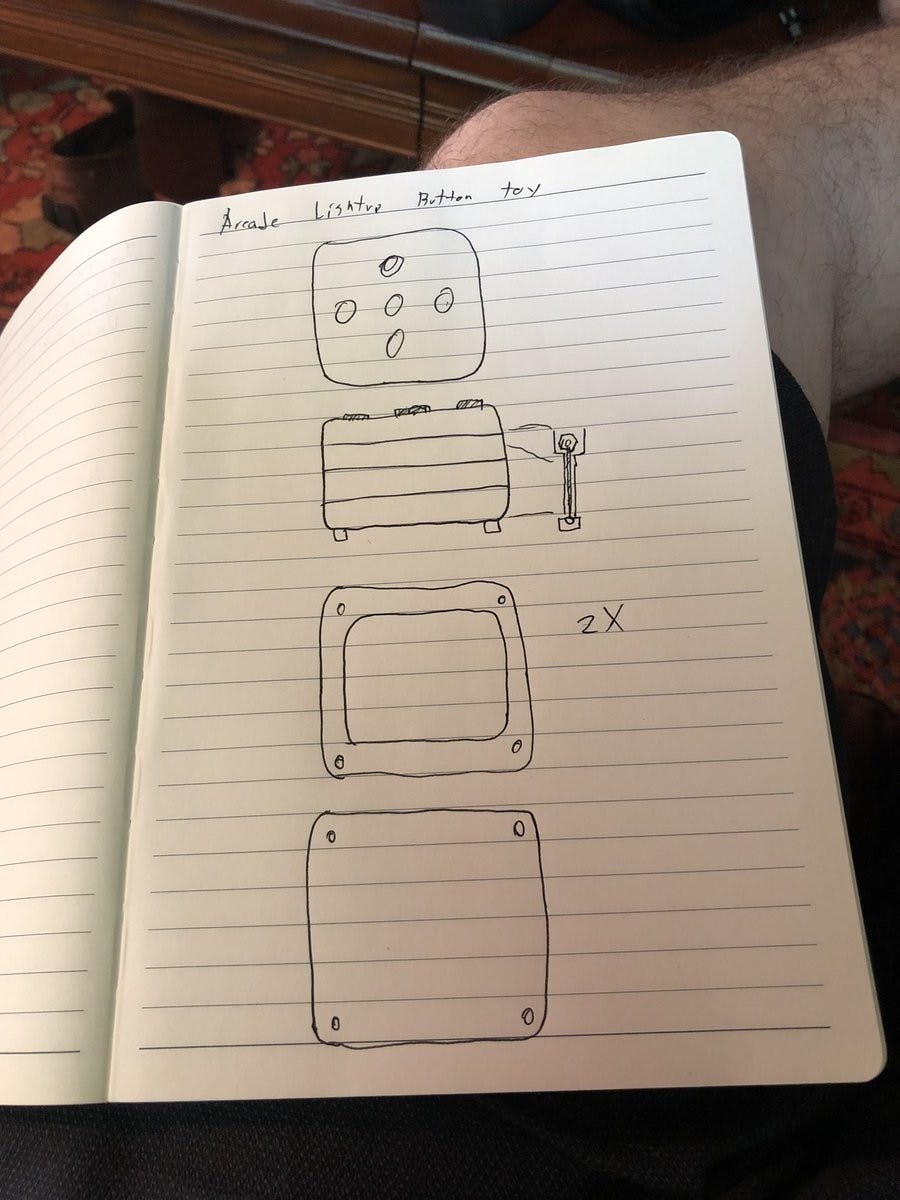

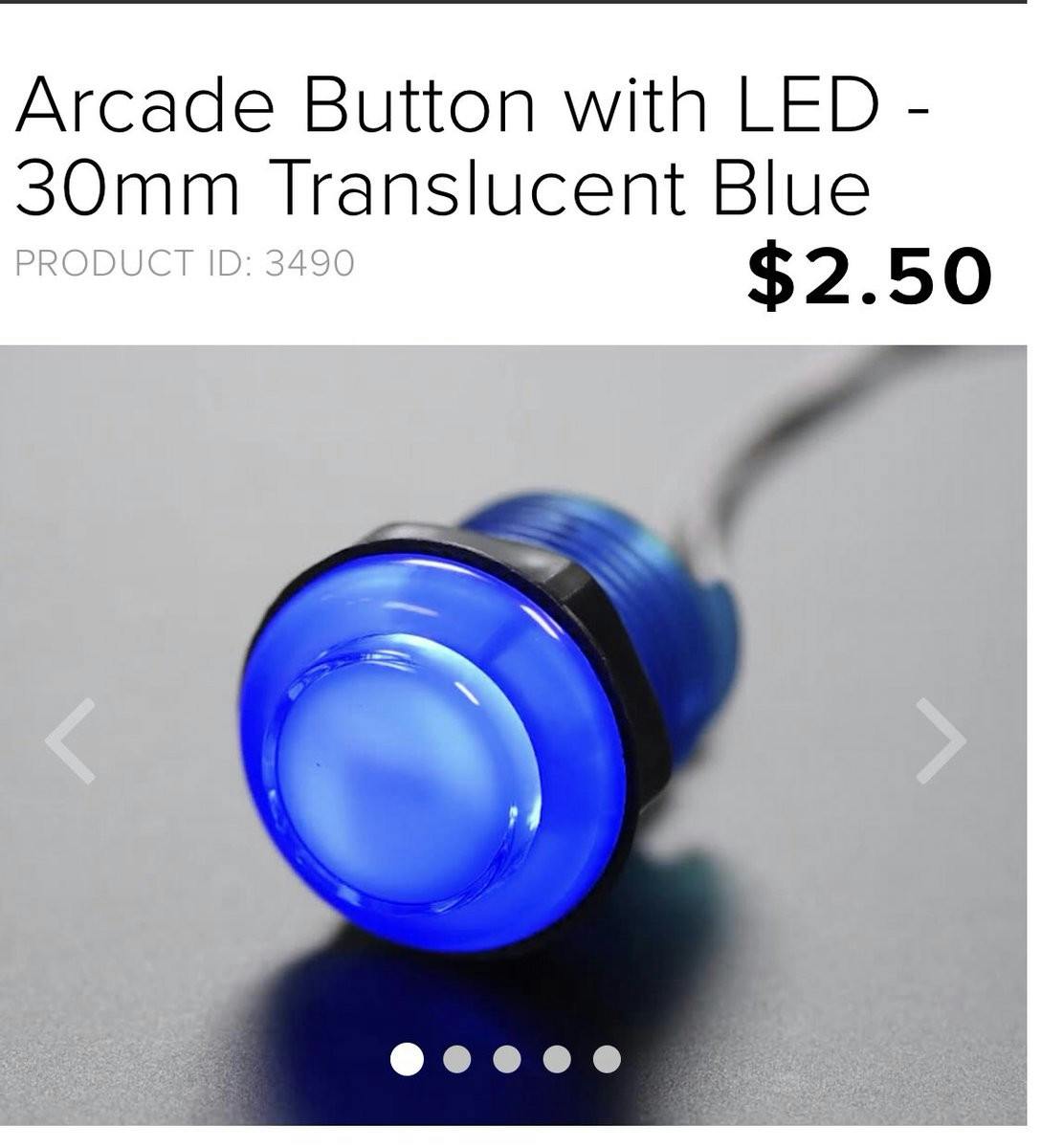

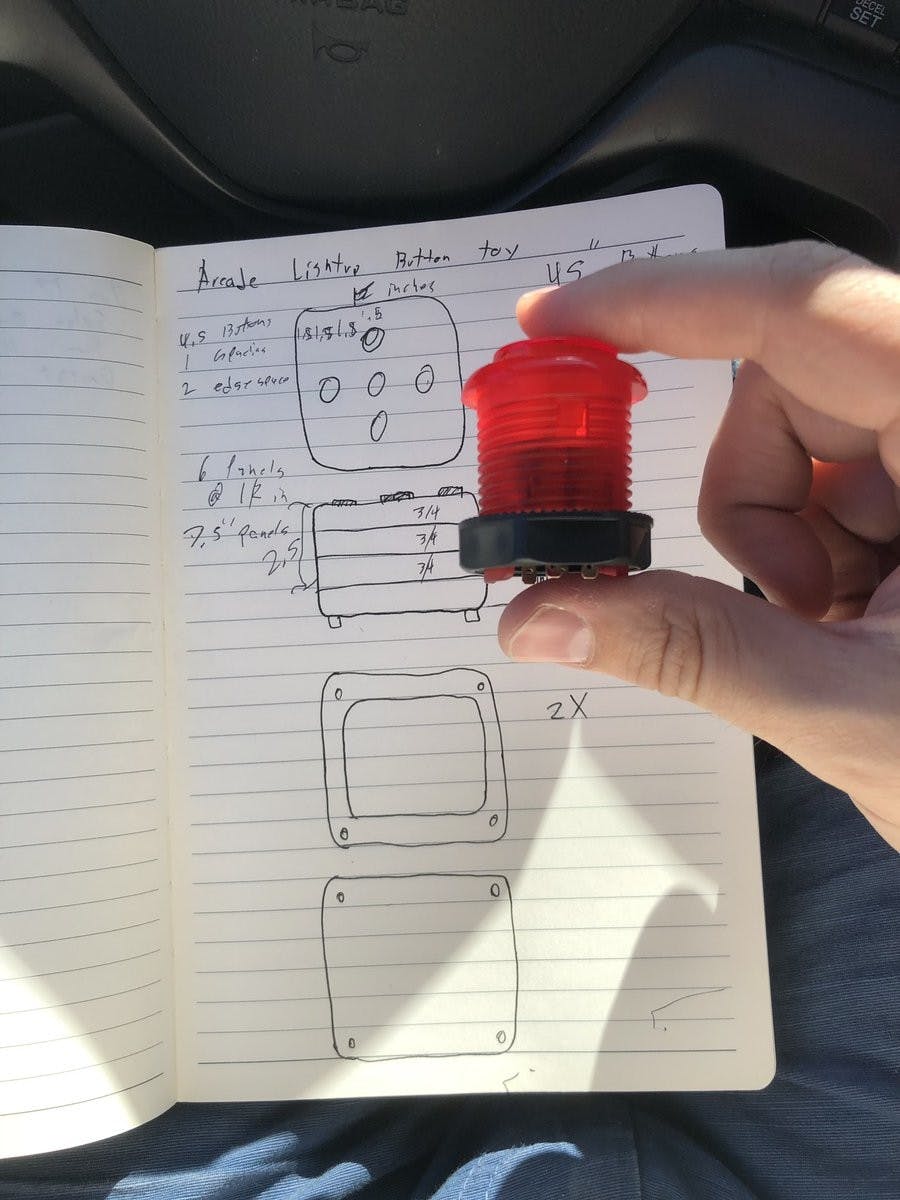

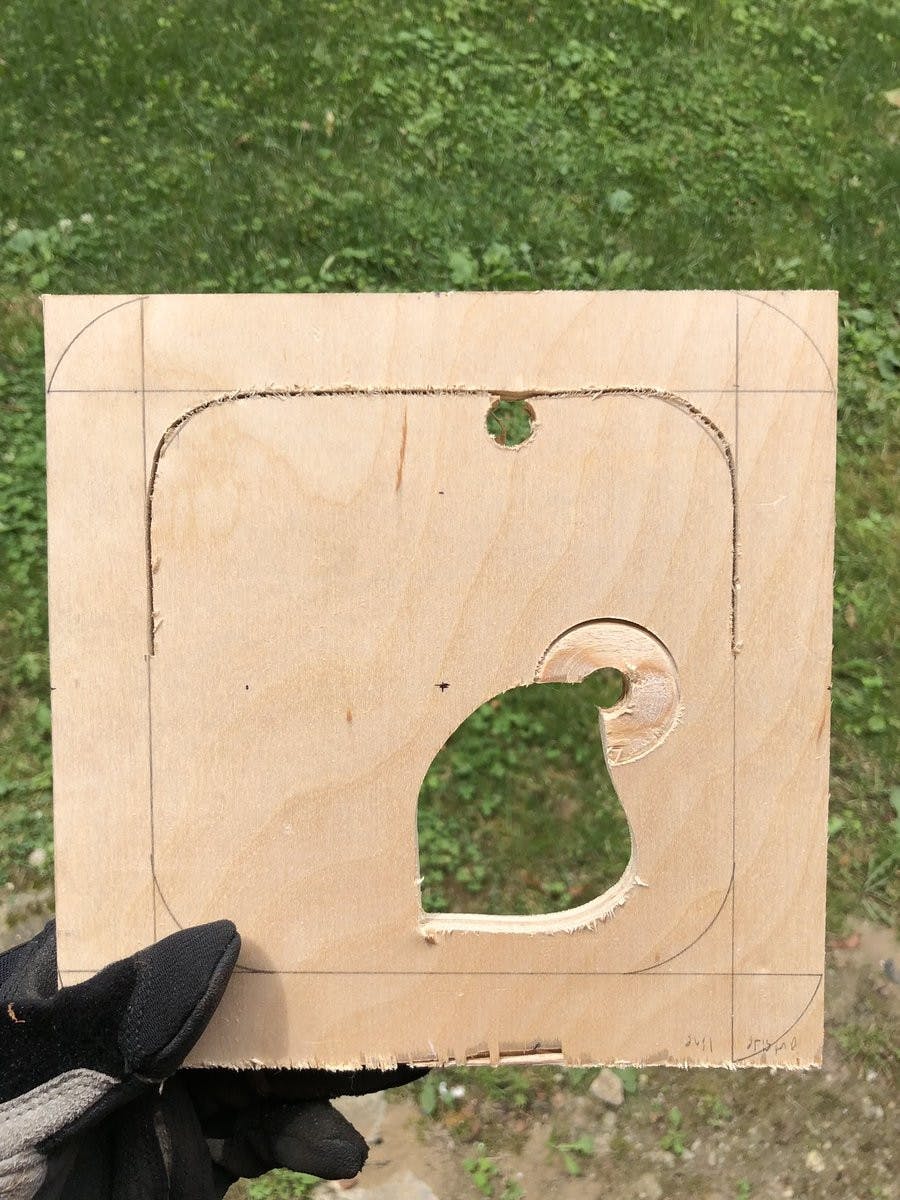

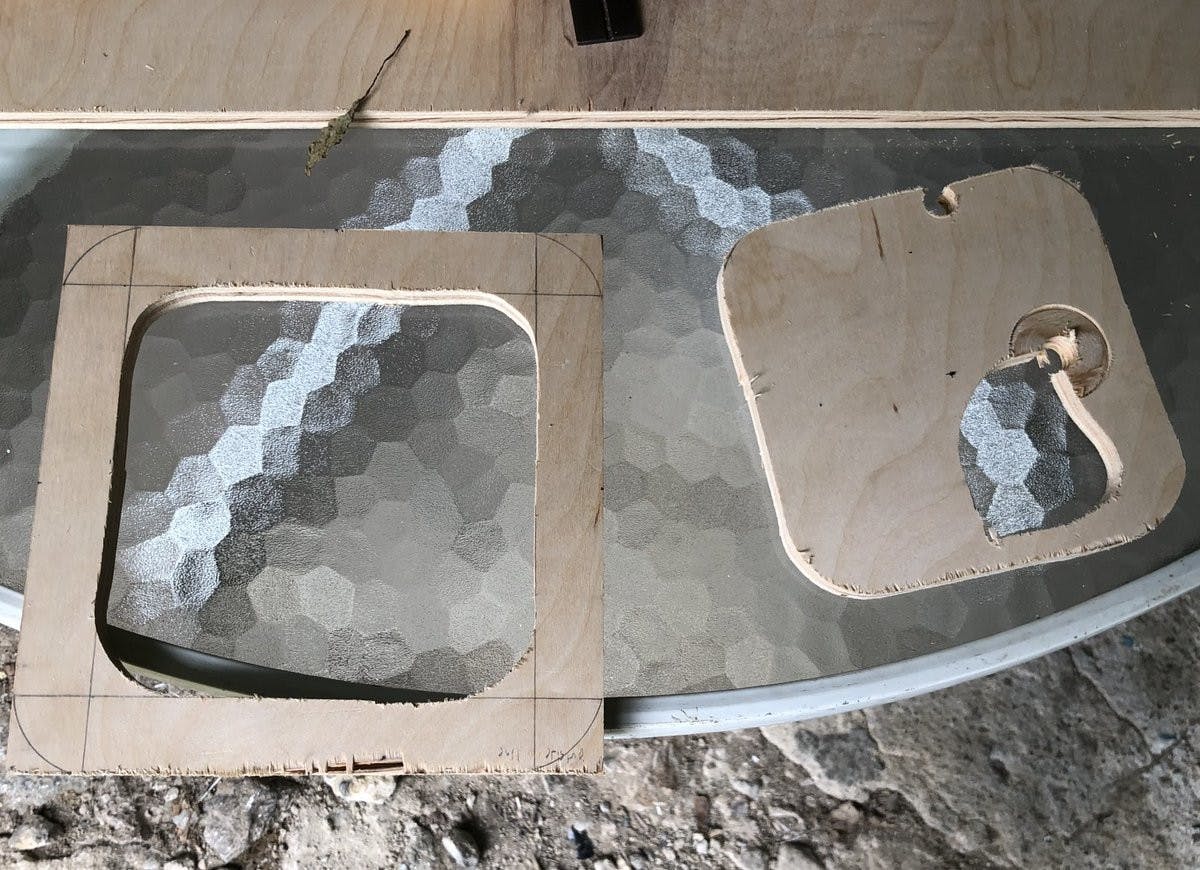

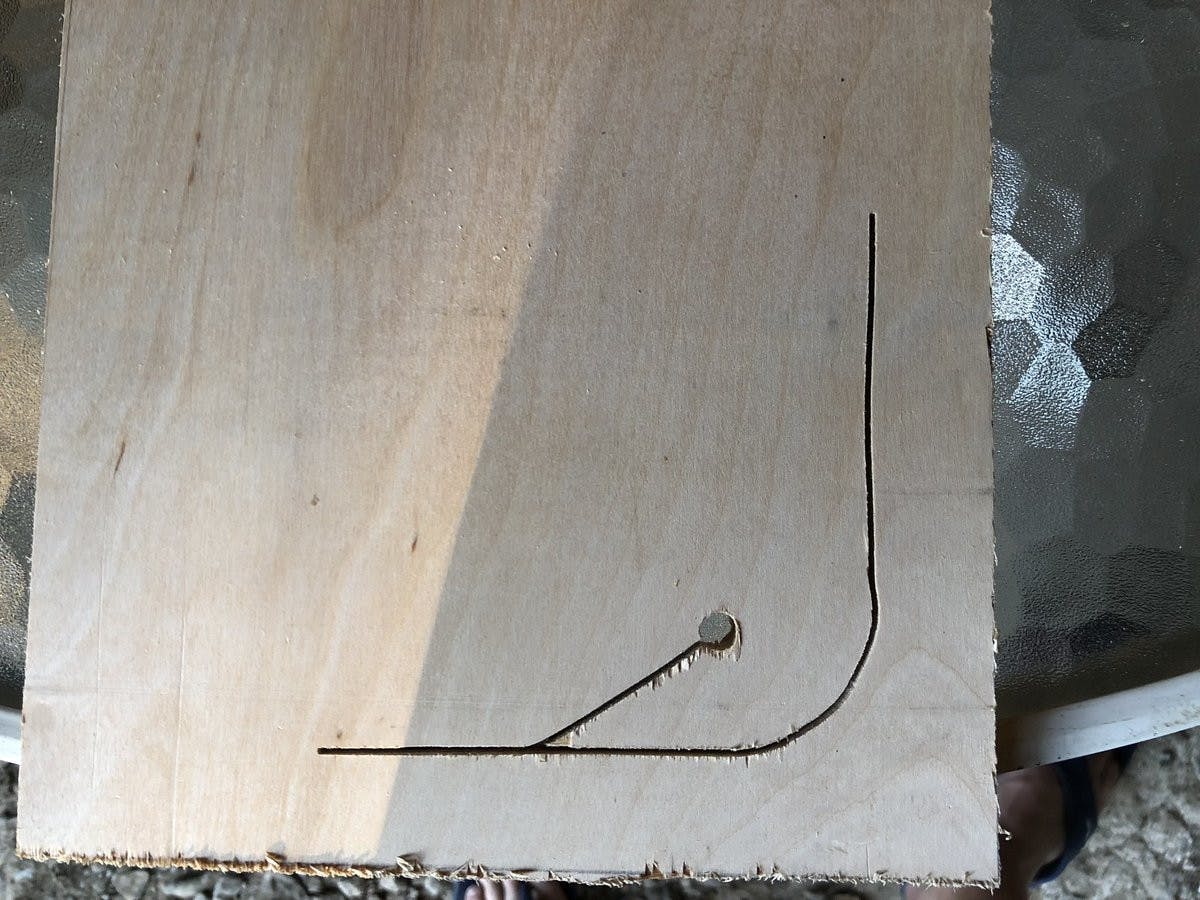

The Button Toy Project

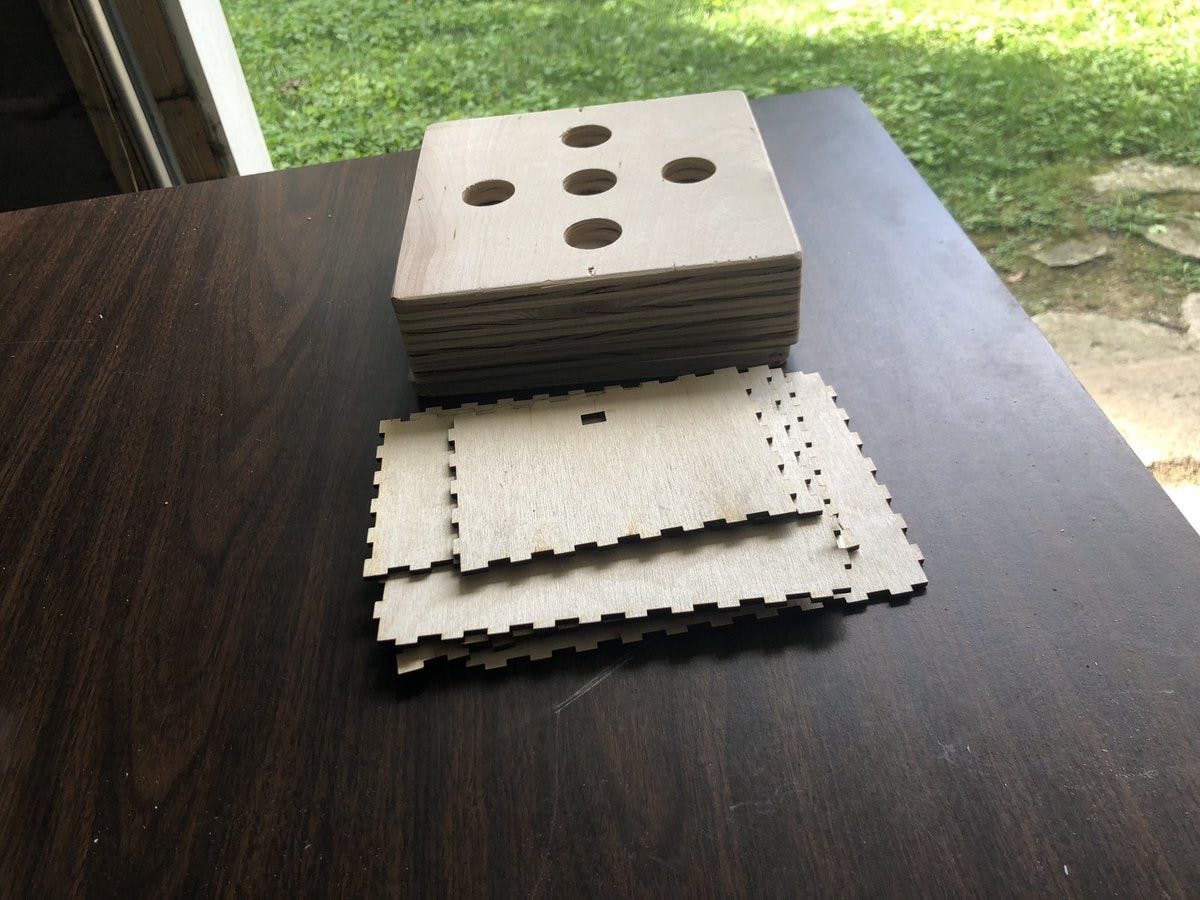

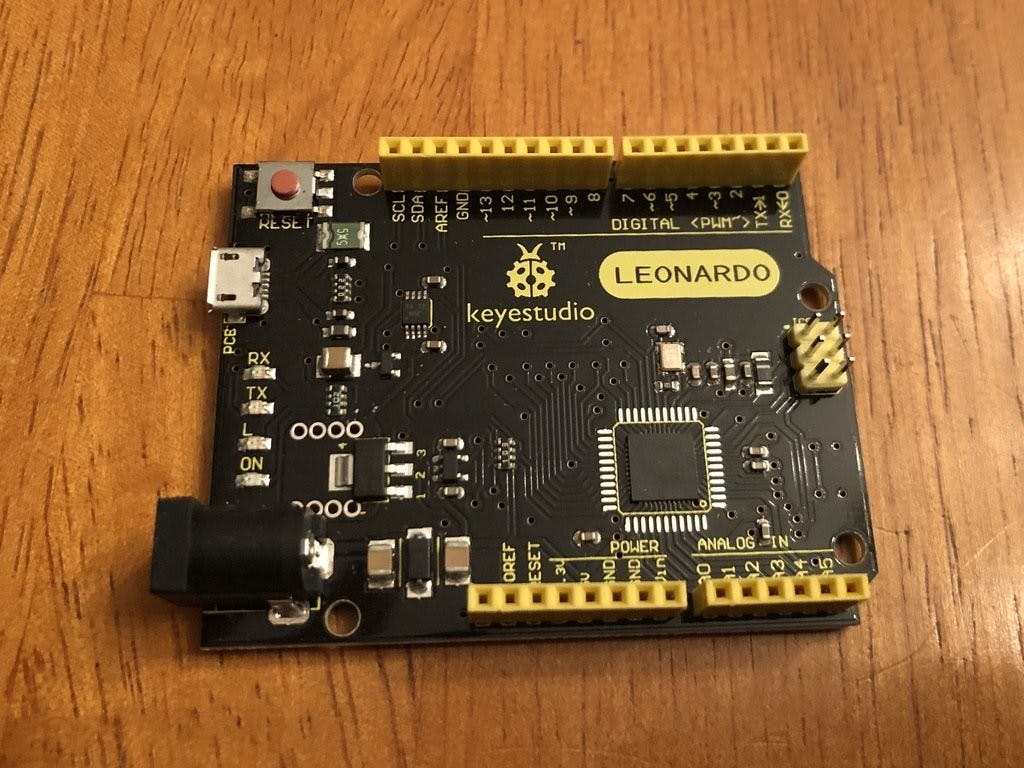

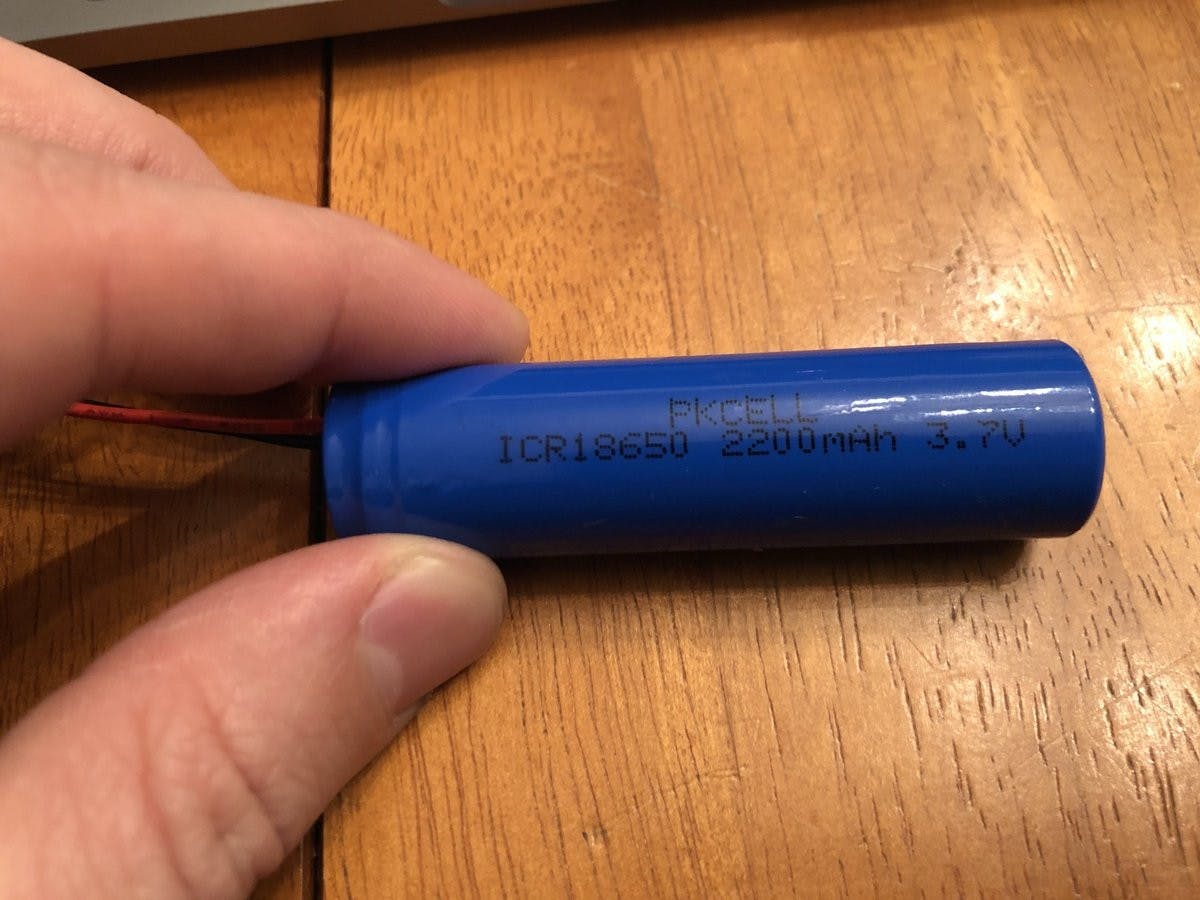

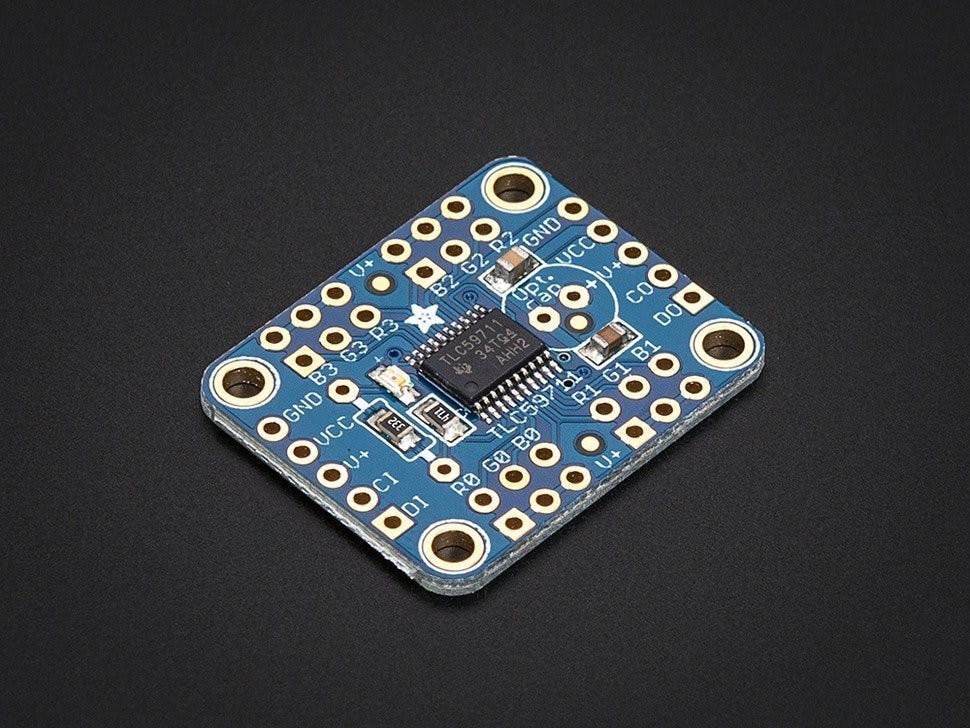

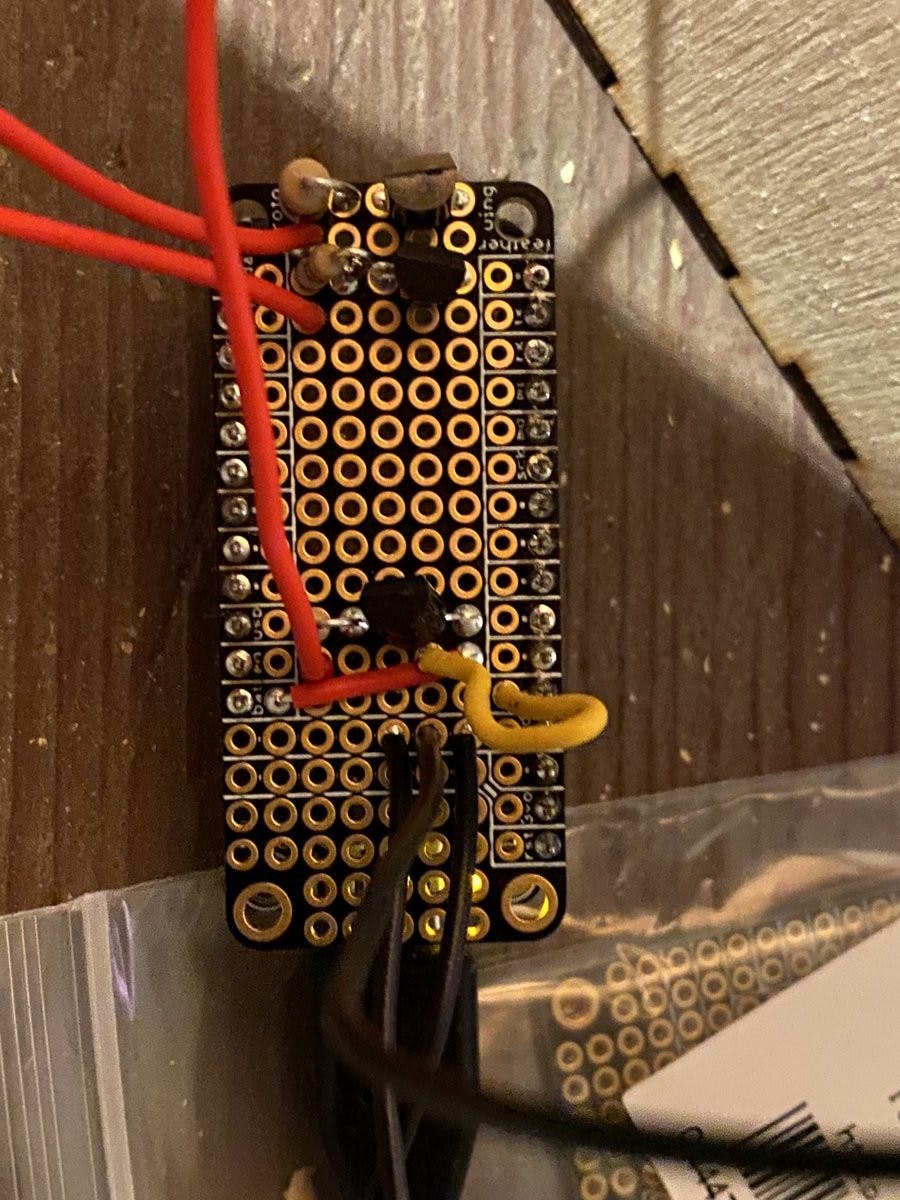

I decided to build a toy for my son. Buttons lights, the works. I’m far from done.

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Francis 🏴☠️ Gulotta

Roborooter.com © 2024

Powered by ⚡️ and 🤖.

Powered by ⚡️ and 🤖.